Sisälogistiikka

Ferroplanin intralogistiikkaratkaisut määrittävät tehokkuuden ja tarkkuuden standardit uudelleen, integroituen saumattomasti ydinprosesseihin ja parantaen tuottavuutta.

Vähennä kustannuksia ja lisää turvallisuutta

ja tarkkuutta materiaalinkäsittelyssä

Sisälogistiikka asettaa yrityksille ainutlaatuisia haasteita, jotka vaikuttavat liiketoiminnan sujuvuuteen ja kannattavuuteen. Ferroplanin sisälogistiikkaan suunnitellut kuljetinratkaisut vastaavat tehokkaasti näihin haasteisiin, tarjoten vankan perustan tehokkaalle työskentelylle.

Tehosta sisälogistiikkaasi Ferroplanin kuljetinjärjestelmillä. Tutustu laajaan valikoimaamme kuljetinratkaisuja ja tehosta materiaalinkäsittelyprosessiesi hallintaa, tai ota suoraan yhteyttä myyntitiimiimme.

Kuljetinratkaisut sisälogistiikkaan

Sisälogistiikassa kuljettimien tarve on välttämätöntä. Kuljettimia tarvitaan kaikissa materiaalinkäsittelyn vaiheissa, tavaroiden vastaanotosta niiden kuljettamiseen tuotantolaitosten sisällä. Erilaiset sisälogistiikkakeskukset, varastoista autoteollisuuden valmistukseen ja lentokenttätoiminnoista postin ja logistiikan tiloihin, tarvitsevat luotettavia ja tehokkaita kuljettimia mahdollistamaan materiaalien ja tavaroiden sujuvan liikuttamisen.

Automaattisilla kuljetinjärjestelmillä on ratkaiseva rooli materiaalivirtojen optimoinnissa tuotantolaitoksissa, varastoissa ja jakelukeskuksissa. Ferroplanin kuljettimet voidaan räätälöidä asiakkaan tarpeiden mukaan yksittäisistä kuljettimista kokonaisvaltaisiin järjestelmiin.

Ferroplan on Interrollin hyväksytty kumppani

Interroll Group on maailman johtava pakattujen tavaroiden ja tuotteiden käsittelyn, sisäisen logistiikan ja automaation toimittaja. Ferroplan on Interrollin hyväksytty yhteistyökumppani ja Rolling On Interroll (ROI) -verkoston kautta osa yli 100 ROI-kumppanin verkostoa joka tuo lisäarvoa materiaalinkäsittelyteollisuudelle hyödyntämällä Interrollin ja sen kumppaneiden kehittynyttä tuoteteknologiaa ja asiantuntemusta.

Interroll tarjoaa tuotteita ja kattavia ratkaisuja eri teollisuudenaloille, kuten intralogistiikkaan, elintarviketeollisuuteen, lentokenttälogistiikkaan, postipalveluihin, jakelukeskuksiin ja muille teollisuudenaloille, tehostaen yritysten materiaalivirtoja. Kauttamme on mahdollista hankkia sekä yksittäisiä Interroll-kuljettimia että räätälöityjä ratkaisuja asiakkaiden erityistarpeisiin. Lisäksi voimme hyödyntää koko ROI-verkoston yhteistyökumppaneiden osaamista.

- Tutustu Interrolliin ja Rolling On Interroll -ohjelmaan

- Ota yhteyttä asiantuntijoihimme, jos olet kiinnostunut löytämään ratkaisuja sisälogistiikan erityistarpeisiin.

Ferroplan kuljetinjärjestelmien

hyödyt

Sisälogistiikan dynaamisessa maailmassa tehokas materiaalinkäsittely on ratkaisevan tärkeää. Erityisesti sisälogistiikan tarpeisiin suunnitellut kevyet kuljetinjärjestelmät takaavat toimintojen sujuvuuden ja tehokkuuden.

Aika- ja kustannussäästö

Automaattiset kuljetinjärjestelmät säästävät merkittävästi aikaa nopeuttamalla tavaroiden siirtoa laitoksen sisällä. Manuaalisen käsittelyn vähenemisen myötä ylimääräisiä työvaiheita ei tarvita.

Suurempi suorituskyky

Kuljetinjärjestelmät mahdollistavat suuremman materiaalin läpimenon kuin manuaaliset menetelmät. Tämä tarkoittaa sujuvaa, nopeaa ja tehokasta materiaalinkäsittelyä. Jatkuva materiaalivirta takaa myös tasaisen ja luotettavan tuotantosyklin.

Optimoitu tilan käyttö

Ferroplanin kuljetinjärjestelmät suunnitellaan aina asiakkaan tarpeiden mukaan, jolloin käytettävissä oleva tila hyödynnetään optimaalisesti ja kapasiteetti maksimoidaan. Kokonaisratkaisun suunnittelussa hyödynnetään esisuunnittelua, jotta lopullinen ratkaisu on optimaalinen ja vastaa asiakkaan tarpeita.

Tarkka seuranta

Kuljetinjärjestelmiin voidaan sisällyttää tekniikkaa, joka mahdollistaa materiaalien tarkan seurannan lajittelua tai paikannusta varten. Virheiden minimointi ja toimitusten tarkkuuden varmistaminen ovat ratkaisevia näkökohtia erityisesti sisälogistiikassa.

Turvallisempi työympäristö

Ferroplanin kuljetinjärjestelmät on suunniteltu turvallisuus edellä. Nykyaikaiset ratkaisumme sisältävät uusimmat turvallisuusominaisuudet ja täyttävät standardit luoden turvallisempaa työympäristöä. Toteutusvaiheessa arvioimme huolellisesti olosuhteet ja tunnistamme mahdolliset vaaratekijät varmistaaksemme, että uusi järjestelmä ei ainoastaan täytä, vaan ylittää turvallisuusvaatimukset. Kun vanhat kuljettimet korvataan Ferroplanin ratkaisuilla, asiakkaat hyötyvät merkittävästi vähentyneestä onnettomuusriskistä ja parantuneesta toimintavarmuudesta.

Ratkaisumme sisälogistiikkaan

Sisälogistiikan optimointi on olennainen osa yrityksen tehokkuutta. Me Ferroplanilla ymmärrämme tämän ja pyrimme auttamaan sinua nostamaan tuottavuutesi uusiin korkeuksiin. Autamme löytämään kuljetinratkaisuja tai varastointijärjestelmiä, jotka tekevät yrityksestäsi entistäkin kannattavamman. Tutustu alla oleviin erilaisiin ratkaisuihimme tai ota suoraan yhteyttä asiantuntijoihimme, niin etsitään yhdessä sinulle paras ratkaisu. Voit myös käyttää kuljetinjärjestelmien huoltopalveluja Ferroplanin FerroCaren kautta.

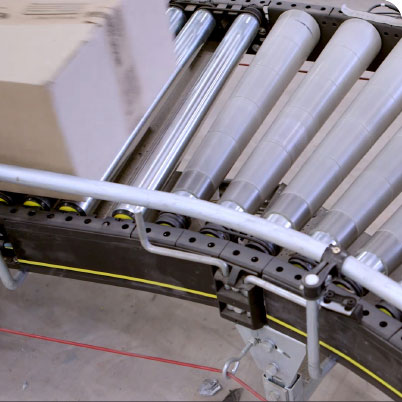

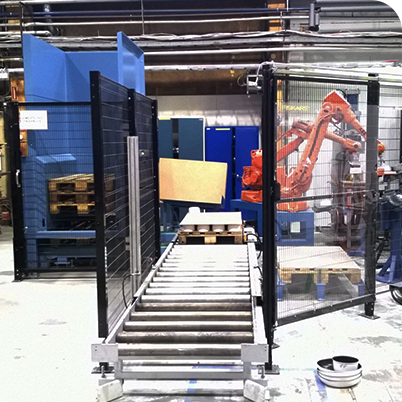

Rullakuljetin

Rullakuljettimet tehostavat sisälogistiikkaa mahdollistamalla nopean ja luotettavan tavaroiden, kuten laatikoiden ja lavojen, hallinnan. Toimitamme myös kaarevia rullaratoja.

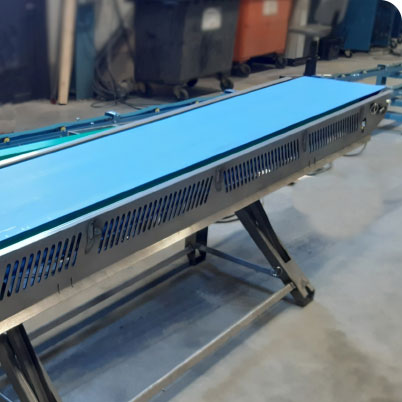

Hihnakuljetin

Hihnakuljettimet soveltuvat laajasti erilaisiin ympäristöihin ja erilaisille tarpeille. Näitä kuljettimia voidaan asentaa erikseen tai konfiguroida osaksi kokonaista kuljetinjärjestelmää.

Ketjukuljetin

Ketjukuljettimet parantavat sisälogistiikan toimintaa siirtämällä tehokkaasti kuormia, myös raskaita tai epäsäännöllisiä tavaroita, varasto- ja jakelukeskusympäristöissä.

Kuljettimiin integroidut kuormalavapinoajat

Edistyksellinen kuormalavojen pinoamis- ja jakeluyksikkö, joka voidaan integroida kuljetinjärjestelmiin. Tämä ratkaisu tehostaa kuormalavojen hallintaa tuotantolinjoilla ja varastoissa. Automaattinen yksikkö sopii sekä puu- että muovilavoille.

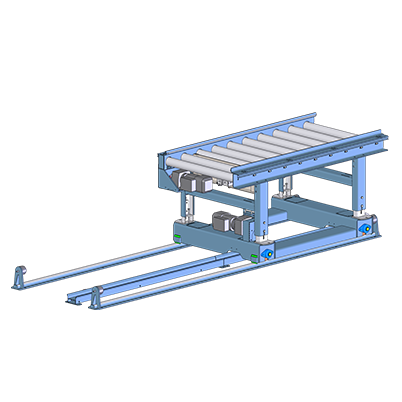

Traverssit

Traverssit tehostavat materiaalien siirtoja erilaisissa tuotantolaitoksissa ja varastoissa. Ne liikkuvat niille suunnitelluilla kiskoilla, ja auttavat materiaalien ja lavojen siirroissa tarkasti ja nopeasti. Traverssien suurin etu on niiden kyky siirtää kuormia ilman manuaalisen työn tarvetta parantaen työn tehokkuutta.