Conveyor solutions for mechanical forest and sawmill industry

Ferroplan conveyor solutions provide a new perspective

for the forest and sawmill industries

Enhancing Efficiency in Production

with Ferroplan Conveyor Systems

Ferroplan’s conveyor systems play a pivotal role in optimizing and enhancing the efficiency of production processes

in the forest and sawmill industry. These systems offer a countless of versatile benefits, particularly in financial and

operational aspects.

Mechanical forest & sawmill industry

The forest and sawmill industry has a significant need for a variety of conveyors. This is because it’s an industry where there’s a need to transport products at different stages from one place to another within production facilities.

Investing in sustainable and innovative conveyors is worthwhile, as it improves production efficiency and enhances overall results. Ferroplan’s conveyor systems are used in various industries, from storage to manufacturing, and from automotive to waste handling. However, we also offer a wide range of conveyors perfectly suited to the demanding environments and specific needs of the mechanical forest and sawmill industry. Ferroplan’s conveyor systems are suitable for handling various wood products at different stages and ensuring uninterrupted production.

Conveyor systems for different applications

Ferroplan conveyor systems facilitate the transfer of various materials within production facilities. From logs, bundles of boards, lumber packages, stacks of battens, to bark, wood chips and sawdust everything can be managed with different types of conveyors. Ferroplan is well-known for its unique conveyor solutions, which means we customize to preciously fit the customer’s needs and production facility.

Different types of measurement and log conveyors are suitable, for instance, for transporting large logs before and after debarking. Various sizes and types of saw feed conveyors, incorporating log conveyors, log kickers, step feeders, and measuring conveyors. They seamlessly collaborate making them an excellent addition to different setups. Additionally, transporting by-products such as wood chips, bark, and sawdust to desired locations is achievable with various belt and trough belt conveyors, ensuring the overall solution for the production facility is clean and reliable.

Specialty conveyors for specialized needs

Through preliminary design, we ensure that each customer’s unique requirement is met. The structure of our conveyors can be tailored to various dimensions and configurations, making it possible to adapt the conveyor system to a wide range of environments.

Ferroplan conveyors can be acquired individually, but we also design comprehensive solutions that address specific customer needs and requirements. In the preliminary design phase, we also address risk management by conducting a risk analysis, model profitability calculations, and create mechanical, automation, and installation plans. Through preliminary design, you can be assured that the result will be an efficient and reliable material handling system, with optimized costs and consideration for space constraints. You can read more about the preliminary design here.

Benefits of Ferroplan

conveyor systems

Customer needs can vary greatly, and for the forest and sawmill industry, we offer conveyor systems that are strong, powerful and designed together with the customer. One thing is certain; installing a conveyor system is essential to ensure a smooth material flow.

Efficiency and Automation

Conveyor systems enable efficient transfer of materials in sawmills and various production facilities in the forest industry. Automation reduces manual labor and increases production efficiency. At the same time, conveyor systems bring significant speed to the production process, reducing waiting times and increasing production capacity.

Waste Reduction

Well-designed conveyor systems help reduce material waste and minimize human errors in material handling, leading to cost savings.

Cost-Efficiency & Quality Control

An automatic conveyor reduces labor costs and saves time in the production facility. Additionally, the conveyor system is the best long-term option, bringing significant savings. Conveyor systems can also monitor and control the movement of materials accurately, improving quality and reducing the possibility of errors.

Flexible and Scalable System

Versatile conveyor systems can be designed to meet various production and customer needs. They are also easily scalable to meet growing demand or changing production models, so if there is a need to expand the product range in the future, the conveyor system does not hinder business expansion.

Enhanced Product Safety

Ferroplan’s conveyor systems are designed with a strong focus on safety, providing significant improvements over existing conveyor lines. Our modern designs incorporate the latest safety features and standards, ensuring a safer working environment. During the implementation phase, we carefully assess existing conditions and potential hazards to ensure the new system not only meets but exceeds safety expectations. By replacing old conveyors with Ferroplan solutions, customers benefit from enhanced safety, reducing the risk of accidents and increasing overall operational security.

Invest in a solution that makes sense

If you’re seeking a fresh perspective on conveyor solutions

for the sawmill or mechanical forest industry, reach out to our experts.

We provide reliable, productive, and safe solutions

tailored to your specific needs. Additionally, you can access conveyor system maintenance services through Ferroplan’s FerroCare.

Our solutions for forest & sawmill industry

We offer a wide range of products and solutions to streamline material handling processes

Storage Systems

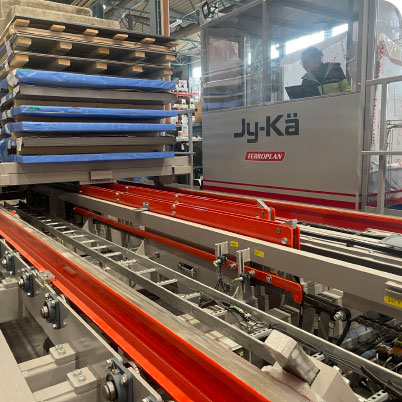

Ferroplan designs specialized storage systems tailored specifically for the unique requirements of the mechanical forest and sawmill industry. Our solutions cater to various storage requirements, including panel bundles, timber packages, and bar bundles

Traverses

Ferroplan’s traverses enhance efficiency and precision, especially in handling large timber stacks, sawn timber bundles and board products.

Measuring Conveyors

Our conveyor solutions feature advanced conveyors specifically engineered to convey logs and boards directly to the measuring systems and then to the required destinations.

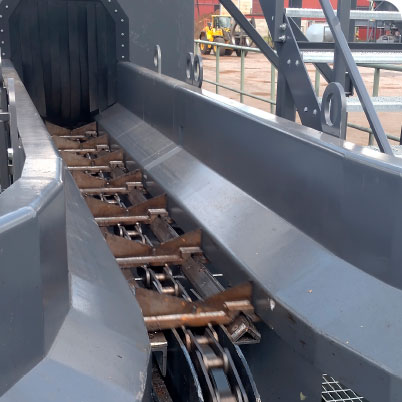

By-Product Conveyors

Designed for reliability and durability, the by-product conveyors ensure efficient handling and disposal of bark, chip, sawdust and similar.

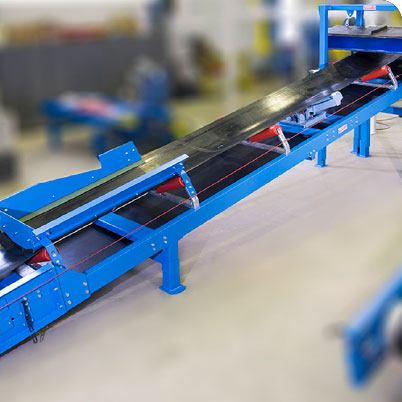

Transfer Conveyors

From transporting logs to maneuvering boards and packages, our conveyors deliver seamless integration and precise handling.

Special Conveyors

From intricate log handling to precise lumber transportation, Ferroplan’s special conveyors are engineered with precision and reliability in mind.

Whether it’s navigating challenging terrain or accommodating irregular shapes and sizes, our solutions rise to the occasion, ensuring seamless integration into existing operations.